You need higher accuracy?

Our suppliers are among the world’s leading companies when it comes to precision.

Air Bearings

Mechanical Bearings

Vacuum or Cryo

Piezo/Nano-Positioning

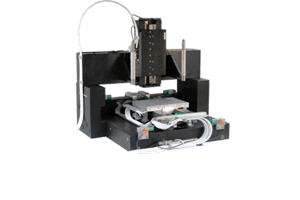

Cross Tables

- air-lubricated bearing

- multi-axis systems

- direct drive with linear motors

- can be protected from the penetration of dirt and dust

- suitable for high-speed applications

- adapted as integrated devices into your control system or fitted with an internal control system

Linear axis

- air-lubricated bearing

- friction-free and stick-slip-free movement

- high precision

- very high repeat accuracy and synchronism

- can be supplied with guide track coverings

- can also be operated as Z-axes

Air bearing round tables

- available as round tables without motors and measuring systems (passive round tables)

- available as direct drive round tables with integrated motor and measuring system (active round tables)

- Highly precise axes have concentricity errors up to 50 nm radial and up to 20 nm axial

- suitable for chip removal operations

basic air bearings, Pads

- Linear systems can be efficiently and economically assembled with basic air bearings (air bearing pads)

- standard air bearings with diameters of 20 mm to 500 mm

- load-bearing capacity of up to 100 kN

- air bearings with integrated suction for cleanroom or vacuum applications available

- rectangular air bearings, high-speed bearings and vacuum preloaded air bearings available

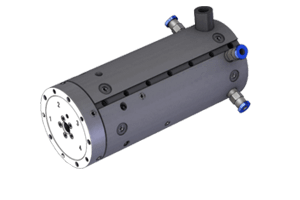

air bearing spindles

- High-precision and high-speed air bearing spindles

- for mechanical processing or scanning

coplanar passive systems and strocke cylinder

- permit movement with several degrees of freedom

- can be clamped by switching off the supply air

- serve to transport thin substrates such as wafers, glass sheets and metal sheet

- operate friction-free, without stick-slip

- ideal for weight compensation in Z-axes

Rotating unions

- designed for the transition of vaccum or air in rotating systems

- no friction because of air bearing technology

- no breakaway torque, no stick-slip effect

- maintenance-free

- high operational life time

- combination of media can be chosen freely

- even suitable for higher rpm

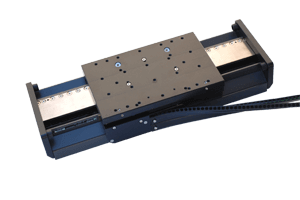

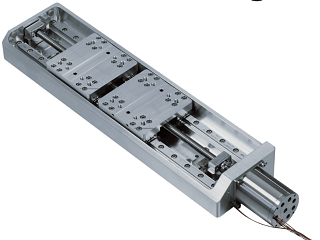

Translation stages

- Travel range up to 2800mm

- 2.5 μm resolution or higher

- X-Y-Z configurations available

- High guide ways accuracy

- Vacuum versions available

Direct-drive motor stages

- Travel range up to 300mm x 300mm

- Accuracy up to ±0.5μm

- High loads up to 150kg

- Bidirectional repeatability up to ±0.5μm

Vertical translation stages

- Loads up to 8kg

- Travel range up to 25mm

- Repeatability ≤ 3μm

- Vacuum versions available

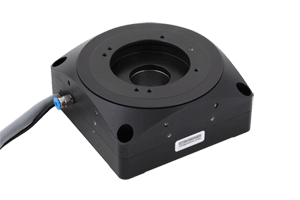

Rotation stages

- With or without aperture

- High load up to 1000kg

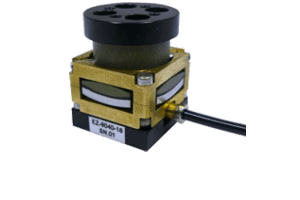

Goniometers

- Smooth operations

- Travel range ±2.5°

- Superb stability

- Stackable (1 or 2 axes of rotation)

motorized iris diaphragms

- Various aperture range

- Smooth and fast operation

- Compact design

Screws and actuators

- Travel range up to 25mm

- High load up to 70N

- Vacuum versions available

custom systems

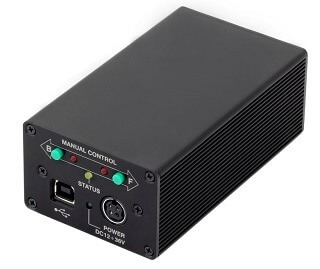

Motion controller

- One controller, one interface for any type of motor (Bipolar Stepper, DC, BLDC)

- Compatible with Windows XP/Vista/7/8/10, Linux, Mac OS

- Max. speed – 35000 steps/s (stepper); 800000 encoder counts per second (DC)

- Code Examples for Visual Basic, C, C#, C++, Matlab, Labview, Python

Vacuum

- Vacuum 10-6 mbar, bake out at 80°C

- High Vacuum 10-7 mbar, bake out at 100°C

- Ultra High Vacuum 10-9 mbar, bake out at 110°C

- Ultra High Vacuum Special

10-10 mbar, bake out at 200°C

Cryogenic

- Standard 77°K

- Vacuum compatible

- R & D 4°K

Piezo Actuators and Stages

Positioning Tools

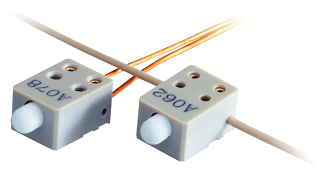

Fiber Switches

Special Solutions

Amplifier